Waste heat utilization

Waste heat utilization description

Waste heat is the energy which is not be used in energy utilization equipment under certain economic and technological conditions, it is called surplus or waste energy. Recovery and utilization of waste heat is an important way to improve economy and save fuel.

With the development of cement industry, the energy-saving technology of cement industry in developed countries has developed rapidly. Low-temperature waste heat is recycled in cement production process, and the thermal energy utilization rate of cement clinker has been greatly improved. However, due to the restriction of energy-saving technology, equipment level and the influence of energy-saving consciousness, there are still a large number of waste heat resources of medium and low temperature exhaust gas not fully utilized in kiln industrial enterprises, and the phenomenon of energy waste is still very prominent.

The waste gas discharged from the clinker cooler and the preheater in the new dry process cement clinker production plant is about 350, Its thermal energy is about 35% of the heat consumption of the cement clinker calcining system. The application of low temperature waste heat power generation technology could recover the waste heat, increase the energy utilization rate of cement plant up to 95%. The economic benefits of the project is considerable.

CONTACT US

Waste heat utilization technology advantages

1. High rate of waste heat utilization, and the comprehensive heat utilization rate can be more than 90%;

2. Reduce fuel consumption and achieve energy saving and emission reduction;

3. High efficiency of power generation;

4. The grade of heat source is low and no afterburning is needed;

5. Independent construction will not affect the regular operation of the cement plant;

6. Comprehensive utilization of waste heat can be realized: heating supply, power supply, hot water supply and etc;

7. It can meet part of the electricity demand of cement plant and relieve the pressure of municipal power;

8. In case of large-scale fluctuation of heat source load and parameters, the operation is not only stable and reliable, but also efficient and stable;

9. Low maintenance costs and technical barriers;

10. Wide range of the heat source applications.

Form of power generation

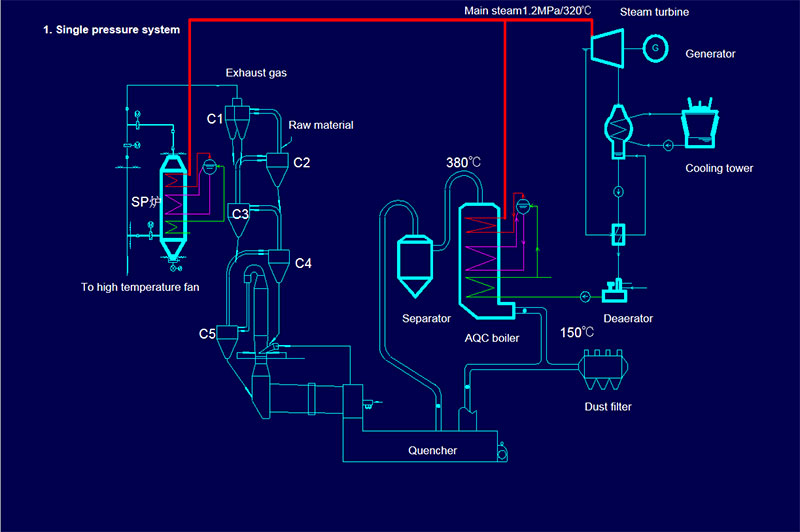

1.Single pressure system:

Simple structure, less investment, suitable for clinker production line plant below 2500 tpd.

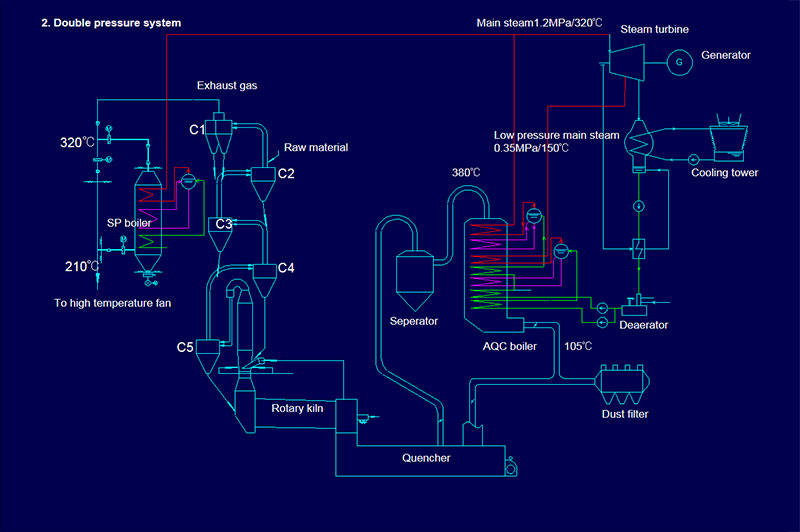

2.Double pressure system:

The structure is more complex, the investment is relatively high, the power generation is 8-10% higher than the single pressure system, and it is suitable for clinker production line plant over 2500 tpd.

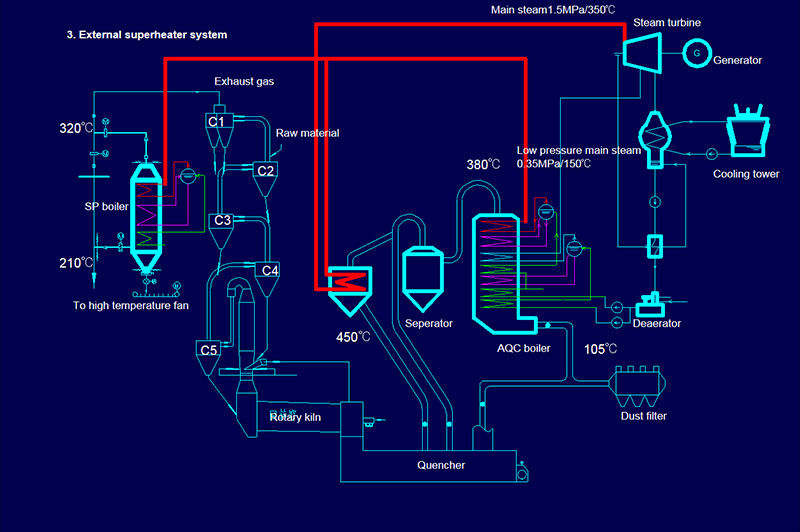

3.External superheater system:

Complex structure, flexible configuration, conducive to the step utilization of waste heat, power generation is 10-15% higher than the single pressure, wide range of application.