First, what is straw returning?

Straw returning is a kind of fertilization and fertilizer increase measure that is universally valued in the world today.

The air pollution caused by stalk incineration also has the effect of increasing fertilizer and increasing production. Straw returning can increase soil organic matter, improve soil structure, loosen soil, increase porosity, reduce capacity, and promote microbial vigor and crop root development.

Second, the harm of straw returning to the field?

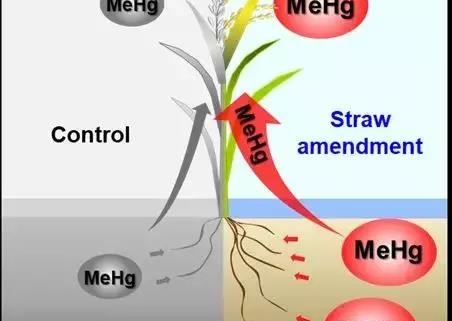

According to a team of professors from the School of Environmental Sciences of Nanjing University, the research progress in the field of mercury biogeochemistry in rice fields found that, unlike the fixed effect on heavy metals, straw returning will greatly increase the accumulation of methylmercury in rice. Methylmercury is highly neurotoxic and can cause irreversible damage to the central nervous system and reproductive system of the human body. In recent years, studies have shown that rice is an important source of methylmercury exposure for inland residents. Therefore, an increase in the concentration of methylmercury in rice may lead to an increased risk of exposure to methylmercury in the population.

Third, how to solve the problem of straw returning to soil contaminated soil?

Faced with the increasingly serious situation of rural straw treatment and disposal, straw returning to the field will lead to the increase of soil pathogens, crop disease aggravation and lack of seedlings (frozen seedlings). Luoyang Building Materials Design and Research Institute takes advantage of industry technology. The straw gasification power generation technology is used to better solve the harm caused by straw returning and burning.

1. What is straw gasification power generation?

Straw gasification power generation is a technology in which biomass such as straw is heated in anoxic state to decompose and vaporize organic matter in the straw to produce a combustible gas. The combustible gas is used to drive the gas turbine to work to generate electricity.

2. Advantages of straw gasification power generation technology:

1) Wide adaptability of raw materials, adapt to various types of biomass straw, leaves and rhizomes;

2) The gas heat value is stable;

3) The tar content in the gas is less than 30mg/Nm3, and the tar produced in the furnace passes the catalytic cracking conversion technology, and the tar content in the equipment is greatly reduced;

4) High power generation efficiency;

5) The ash after gasification is a good return to the potash.

The straw gasification power generation technology of Luoyang Building Material and Architectural Design and Research Institute has changed the rural straw from disordered incineration to centralized treatment of power generation and fertilizer production, saving a lot of coal resources and increasing farmers’ income. Straw does not increase the amount of CO2 in the atmosphere during growth and combustion, and the sulfur content is extremely low, only 0.1%. The development of biomass power generation, replacing coal, can significantly reduce greenhouse gas emissions and has enormous environmental benefits.