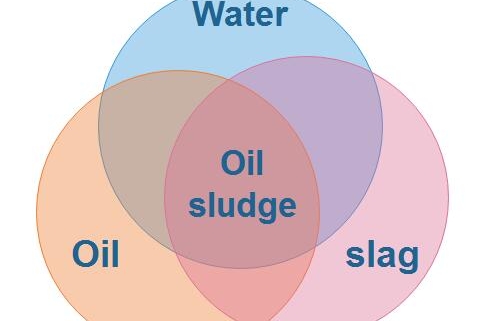

The oil sludge is mainly composed of three phases of water, oil and slag. The characteristics of oil sludges of different types and different sources vary greatly. The content of the three-phase components in the oil sludge will directly determine the available value of the oil sludge, and also processing this type of oil sludge process provides initial parameters. The specific resistance of oil sludge is very large, almost 40 times that of ordinary oil sludge, and its compressibility coefficient is 20 times larger than that of general oil sludge. Therefore, oil sludge belongs to difficult-to-filter oil sludge.

The water content of oil sludge is generally relatively large. For example, the water content of oil sludge in refinery is generally above 60%, and the moisture content of ground oil sludge is as high as 30%. The water and oil in oil sludge form oil-in-water. The difficult state of water-in-oil separation. In addition, a large number of different types of chemical treatment agents, as well as a large number of water treatment agents such as coagulants, fungicides, scale inhibitors, and scale inhibitors, are added to the crude oil extraction and subsequent treatment processes. The contamination components in the oil sludge are made more complicated, and the added additives interact to form a stable and fully emulsified structure, making it difficult to separate the three phases. The oil sludge usually contains a relatively high concentration of heavy metals. The oil sewage from the refinery is added with polymeric iron and polyaluminum in the treatment, resulting in high iron and aluminum content in the oil sludge.

Oil sludge has been listed in the HW08 waste mineral oil in the “Dangerous Waste List”. The oil sludge is complex in composition. In addition to containing a large amount of petroleum, it also contains various types of bismuth, phenols, benzenes, and strontium. Toxic and substances, a large number of pathogenic bacteria, parasites (eggs), heavy metals such as Cu, Zn, Cr, Hg, Pb, salts and polychlorinated biphenyls, dioxins, radioactive nuclear elements and other toxic and harmful substances that are difficult to degrade. The hazard to the soil is generally that the oil sludge will occupy a large amount of agricultural arable land if it is not treated and piled up, which will increase the shortage of land resources; it will also change the original nature of the soil, affect the growth of soil vegetation, and cause soil microorganisms. The species cannot survive and the soil ecosystem is destroyed. During the long-term open-air stacking of oil sludge, the toxic and harmful substances such as organic matter, heavy metals and pathogens are leached by the water stream and the rainwater is leached, and the surface water is remitted with the water. Infiltration into groundwater will cause the groundwater COD, BOD and other indicators to exceed the standard seriously; the volatile substances contained in the oil sludge will slowly diffuse into the surrounding atmosphere, producing a foul smell and unpleasant smell, and the benzene series contained in the volatile matter. Substances are carcinogens, and long-term exposure is extremely harmful to human skin and mucous membranes.

The oil sludge pyrolysis gasification device can separate the oil sludge with high oil content and extract the oil in the sludge. This process not only solves the environmental pollution, but also realizes considerable economic value and has broad application prospects.