Micro powder production line

LCDRI micro powder production line integrates the functions of fine crushing, grinding, drying, powder selecting and conveying, with the advantages of high grinding

Micro powder production line technology advantages

- High efficiency and energy save: high efficiency of powder grinding and separating, high product fineness;

- Smooth and simple process: easy maintenance and low operation cost;

- Environmental protection: dust and noise emission over than national standard;

- Continuous stability, excellent quality: stable product quality, annual continuous operation time can reach 300 days;

- High cost performance: low cost of comprehensive investment;

- High degree of automation: DCS automatic control system for whole production process;

- Advanced technology and equipment: adopt advanced technology and equipment, with stable and reliable operation.

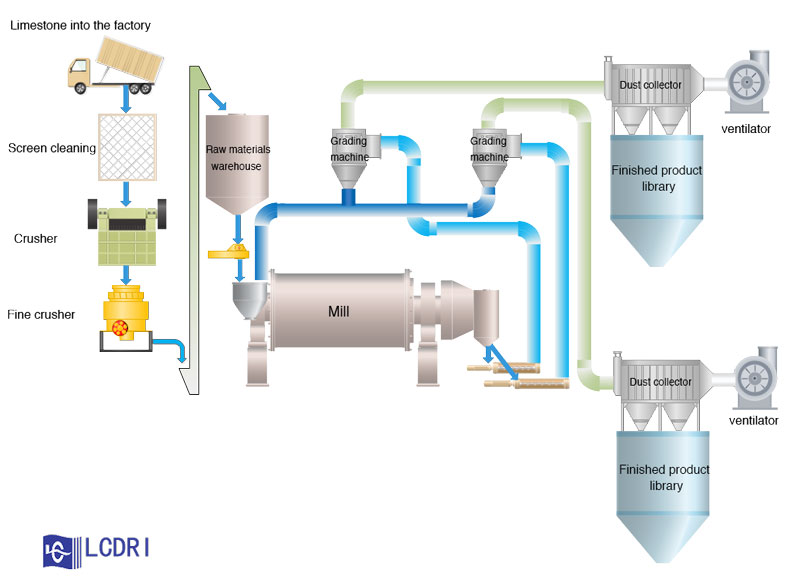

Micro powder production line process flow

After cleaning, the high quality and whiteness calcite raw materials, which were crushed and screened, entered secondary crushing, and the particle size of the crushed calcite was less than 3-6 mm. After the material have been lifted and fed into the feeding bin, and then the metered raw material is fed into the ball mill for grinding. Through the air separation, the grinding powder have been sent into the elevator, under the action of pneumatic suction, the powder is entered into the separator for particle size classification. The product fineness can be adjusted arbitrarily from 800 to 5000 meshes. The qualified fine powder is carried into the special high-pressure pulse bag filter by air flow, and the finished product is collected and sent to the storage. The coarse powder classified from the separator shall be sent to the ball mill for grinding again. The whole system forms a closed-circuit cycle processing system.

If the product fineness needs to be improved, the separation process steps can be increased many times in order to produce higher fineness product.

The production system is operated under negative pressure, and dust collectors are set at dust-raising points in order to prevent dust-raising.

The system equipment adopts advanced DCS control operation, which can control the running of the whole production system in the central control room and improve the working environment of operators.

Main technical characters

Dry process ball mill technology

1、Special design was adopted to optimize the length-diameter ratio of ball mill and improve the grinding efficiency.

2、The grinding fineness of the product is improved by using a scientific graded grinding medium.

3、Rolling bearing + dry oil lubrication is adopted in transmission bearing, which remove the thin oil lubrication station and reduce the operation cost.

4、The product fineness can reach 5000 meshes by pure dry process method.

5、Advantages of the product: narrow particle size distribution range, continuous and stable production. Particles are spherical, with large specific surface area, good filling effect and refractive effect, which can meet the requirements of end users.

The accurate air classification technology

Adopt multi-level separator and separating process, the multiple fineness levels are separated to meet the needs of different customers. The multi-rotor classifier was developed by our company could reach 90% classification efficiency.

The primary classification fineness can be adjusted from 500 to 3000 meshes. Adding the secondary classification system can reach the advanced level at home and abroad.

Ultra low emission

Compact and reasonable layout; negative pressure operation without dust leakage, meet the emission requirements.

Adopt DCS control technology in the whole production system

The whole production system adopts one-key DCS central control system to realize intelligent production process control for crushing, grinding, separating, storage, packaging, loading and transportation. It ensures real-time production monitoring, ensures the continuous stability of the system, the stability and reliability of product quality, and reduces production costs.

Project case

Nanyang Zhongrui Micropowder Production Line designed by our institute in 2016