Waste treatment plant

Description of rotary kiln incineration systems

Rotary kiln incineration systems are ideal for processing mixed industrial and hazardous wastes that include a combination of solid, sludge, and liquid waste streams. LCDRI provides complete rotary kiln incineration packages including a broad range of waste storage and feed systems (ram feeders, sludge feed systems, liquid injection systems), complete combustion system packages, and many different options for continuous ash removal. Rotary kiln incinerators can be paired with custom engineered air pollution control systems for a turnkey solution to control your environment.

For more than 10 years, clients worldwide have been utilizing thermal treatment systems engineered by LCDRI. Our incineration and thermal treatment technologies process a wide range of industrial hazardous wastes including solid, liquid, sludge, and gaseous waste streams generated by commercial, industrial, and medical applications.

LCDRI provides you with a single source of expertise for both the environmental engineering and the equipment you need for a complete thermal treatment system. Our engineers can work with you from day one of your project, beginning with waste characterization studies and environmental permitting, through actual equipment design.

We will custom engineer a fully-integrated package for your unique application including all required systems components, from waste storage and handling through the final air pollution control system.

Key points

- The highest level of flexibility for simultaneously processing a wide variety of mixed waste streams with large variations in heating value;

- Secondary residence time of 2.0 seconds minimum;

- Temperatures to 1100ºC (2012ºF);

- Wet and dry ash removal;

- Wet and dry scrubber air pollution control systems;

- Heat recovery to produce steam or hot water;

- Tolerant of highly varied waste sizes and properties;

- Available in slagging or nonslagging models.

CONTACT US

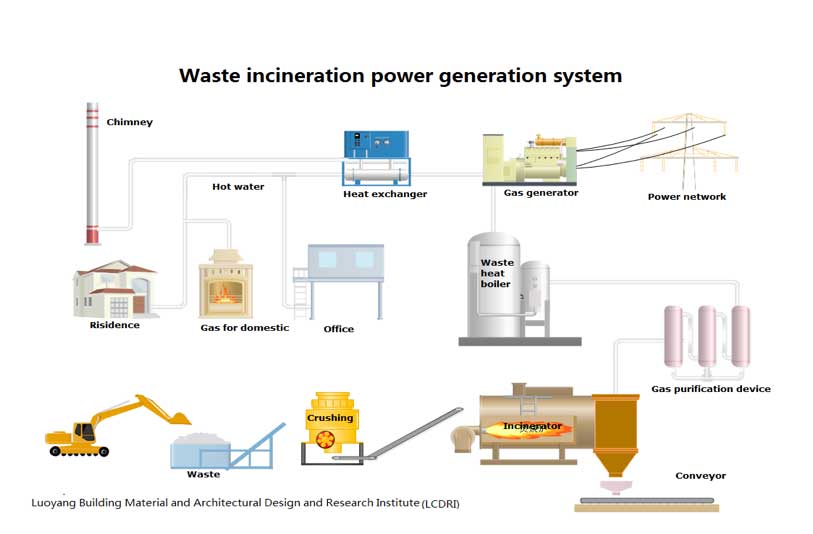

Waste treatment process flow

Domestic garbage is transported to the power plant by the garbage closed transport vehicle → electronic truck scale is overweight → unloading .Into the closed garbage pit → garbage through the grab → feed hopper → pusher → incinerator, high temperature combustion in the incinerator, the flue gas generated by incineration heats the water and generates steam, which drives the steam turbine to generate electricity and incinerate The flue gas is discharged by the exhaust gas treatment device and discharged to the standard. The slag generated by the incineration can be treated as general waste, and the fly ash treated by the bag filter is solidified as a hazardous waste with cement and a chelating agent.

Waste treatment incineration systems

① Municipal Waste Incineration Systems

Municipal waste introduction

Municipal waste incineration system is designed with the consideration of several types of municipal wastes; including paper/cardboard (packing material), plastic (foil, bottles, and dishes), metal cans, food-waste, cloth, garbage etc.

LCDRI Incineration system provides an effective means of reducing the volume of MSW as well as providing an important source of energy. Produced steam can be used purpose of heating or power generation.

Working Principle

(1) Waste is turned into ash and combustible gases at 1000ºC in primary chamber and primary chamber is designed as a rotary kiln for the systems with the capacities higher than 300kg/h;

(2) If hazardous wastes with a content of more than 1 % of halogenated organic substances, expressed as chlorine, are incinerated, the temperature has to be raised to 1100 °C for at least two seconds”. LCDRI Incinerators are designed in such a manner that gases originated during the incineration of wastes in the main combustion chamber are re-burnt with excess air at 1200 °C during 2 seconds in the post combustion chamber;

(3) In order to be fully in compliance with the desired Emission Standards, LDRI Incineration Systems includes flue gas treatment units. Flue Gas Treatment in these systems is multi pollutant control approach to remove the hazardous content of combustion gas originated due waste incineration.

Specification parameters of waste incinerator

|

Specification |

Prod.capacity |

Rotation speed of kiln body |

Main motor |

|

m |

t/d |

R/min |

kw |

|

Ø2.5×13 |

50 |

0.06~3( rotational speed is adjustable) |

15-22 |

|

Ø2.9×13 |

100 |

0.06~3(rotational speed is adjustable) |

22-37 |

|

Ø3.4×17.5 |

150 |

0.06~3(rotational speed is adjustable) |

45-75 |

|

Ø3.8×21 |

200 |

0.06~3( rotational speed is adjustable) |

55-90 |

② Industrial waste incineration system

Technical advantages

(1) The equipment can simultaneously incinerate solid waste, liquid, gas and adaptability to incineration;

(2) The incineration material is tumbling forward, and the three heat transfer modes coexist with one furnace, and the heat utilization rate is high;

(3) Build refractory materials for different materials, so that the service life of the lining is longer and the maintenance cost is low;

(4) The transmission mechanism is simple, the transmission mechanism is outside the kiln body, which makes the equipment operation and maintenance simple; the drive adopts the frequency conversion speed regulation motor, which can flexibly adjust the kiln body speed and control the material residence time;

(5) Long residence time in the rotary kiln and high temperature of 1100 °C, so that the hazardous waste is fully pyrolyzed and the discharge reaches the standard;

(6) For different hazardous waste design, there are many forms such as graphite seal and fish scale seal. Good sealing measures and negative pressure of the furnace to ensure that harmful gases are not leaked;

(7) The equipment operation rate is high, the annual operation rate is generally over 90%, and the operation and maintenance are convenient;

(8)Adding a coke-preventing device in the rotary kiln to adapt to the processing requirements of different materials;

(9) Waste Heat be Reused Effectively,The two sides of the reliable rotary kiln are sealed by the combined scales, which can make the air leakage coefficient less than 10%. Composite refractory materials should be used in order to reduce the loss of radiant heat.

③ Hazardous Waste Incineration Systems

Working Principle

(1) Hazardous wastes can be in the form of liquid, solid, gas, or sludge. All hazardous waste in the form of solid, liquid, gas and sludge can be destroyed by Santes Incineration system;

(2) Hazardous Waste Incinerators has two combustion chambers. In the main combustion chamber wastes are incinerated in 900 oC with the principle of starved air incineration and the flue gas originated in this chamber is directed to the secondary combustion chamber. In the secondary combustion gases formed during the incineration of wastes in the main combustion chamber are re-burnt at 1200 °C during 2 seconds. Excess air is provided to the secondary combustion chamber to achieve complete combustion of organic content of the waste;

(3) Hazardous waste has high calorific value so it can be used as a source of energy. Therefore, in the incineration process, it requires less fuel to increase its temperature to 1200 oC. Waste energy most often recovered as steam can be used to generate electricity;

(4) In order to be fully in compliance with the desired Emission Standards, LCDRI Incineration Systems Includes flue gas treatment units. Flue Gas Treatment in these systems is multi pollutant control approach to remove the hazardous content of combustion gas originated due waste incineration.

Technical advantages

1. Hazardous waste incineration method is suitable for a wide range of hazardous wastes such as highly flammable, volatile, toxic and infectious waste streams which should not be landfilled;

2. LCDRI Incinerators designed to be fully in compliance with desired emission standards;

3. Moisture content causes no problem;

4. Produces clean ash in small volumes;

5. Produces no dioxins even with added chlorine;

6. Product gas has a much higher heating value;

7. Possibility of energy recovery.

④ Animal waste incineration system

Introduction

Animal wastes from various sources need to be handle with special care. LCDRI offers well-suited solutions for specifically designed for your animal wastes.

Animal Carcass Incinerators are designed specially for safe destruction of animal by-products originated from various sources and listed above. Animal by-products (ABPs) are described as animal carcasses, parts of carcasses or products of animal origin that are not intended for human consumption. This includes catering waste, used cooking oil, former foodstuffs, butcher and slaughterhouse waste, blood, feathers, wool, hides and skins, fallen stock, pet animals, zoo and circus animals etc.

Technical advantages

1. LCDRI animal waste incinerators are designed in such a way that the gas resulting from the process is raised in a controlled and homogeneous fashion, even under the most unfavorable conditions, to a temperature of 850 oC with 2 second residence time;

2. LCDRI animal carcass incinerators can be manufactured as mobile especially for the applications of incineration.