In recent years, the state has promulgated a large number of regulations and systems on environmental protection and resource utilization. Environmental protection is the most important concern of major enterprises and factories. Once there are any environmental protection problems, enterprises are not only facing fines and rectification, but also likely to face such major events as shutdown of production and closure, which affect the survival of enterprises. Environmental protection awareness has been deeply embedded in the operations of major enterprises. Among the principles, resource utilization is the lifeblood of upstream raw material enterprises. Rational use of resources, saving resources and reducing pollution emissions can effectively improve the competitiveness of enterprises and achieve win-win environmental and economic benefits. Sandstone aggregate production line, as the front end of the raw material supply chain in the construction industry, its production technology and technology play a vital role.

Sandstone aggregate production line usually includes several systems: 1. crushing system, 2. semi-finished product storage system, 3. medium and fine crushing system, 4. screening system, 5. finished product storage system, 6. loading weighing system, 7. water supply and water treatment system, 8. electrical automation system, 9. spare parts and maintenance center. Following is a general introduction of three common sand aggregate production line process:

The first type of process:

It is suitable for crushing soft and low abrasive rocks, such as limestone, etc. It is a typical process of most commercial sand aggregate processing systems at present. The process is simple and the equipment configuration is few.

Bar feeder is equipped before crushing. Bar feeder has the function of uniform, stable feeding and screening. Material on bar screen enters jaw crusher to crush, which improves the production efficiency of crusher and reduces the wear of liner. According to the situation of material source, the material under bar sieve can enter the regulating stockpile together with coarse aggregate, and can also enter the desilting sieve machine for desilting. The waste of useful material can be greatly reduced and the purpose of desilting can be achieved.

Regulating stockpile is usually set before crushing. Because of the discontinuity of automobile transportation, adjusting stockpile can ensure the continuous and stable production of follow-up process in a certain period of time and improve the utilization efficiency of equipment. At the same time, when crushing temporary overhaul or treatment of oversize stones, the follow-up process is not affected much.

Medium crushing adopts counter-impact crusher, and the crushed aggregate enters the pre-screening workshop. Among them, the aggregate that meets the specifications enters the finished aggregate pile, the over-diameter aggregate enters the fine crushing workshop, and the rest enters the finished product screening workshop for screening, and the finished aggregate that meets the requirements enters the finished aggregate pile.

The second type of process:

It is suitable for crushing hard and high abrasive rocks, such as granite and quartzite. Major use of the cone crusher “lamination crushing” principle, the finished coarse aggregate through two cone crushing, get better particle shape.

Aggregate after medium crushing enters the pre-screening workshop, and fine aggregate less than 5 mm is screened out through pre-screening. All coarse aggregate enters the fine crushing workshop for crushing. Aggregate after fine crushing enters the finished product screening workshop again. Among them, aggregate that meets the specifications enters the finished product aggregate stack, over-diameter aggregate enters the fine crushing workshop, and adjusting buffer bin is set up in the fine crushing workshop when the related host or other equipment. When emergency shutdown occurs, the silo can play the role of storage, reduce the risk of full chamber and belt conveyor starting with load after the main engine stops. At the same time, the adjusting function of the silo can make the fine crushing chamber full of feeding, so that the aggregate shape of the finished product is better and the wear of the equipment is lower.

Better aggregates can reduce the amount of cement, increase workability, reduce the probability of blocking pipelines by pumping concrete, and reduce the cost of concrete mixing station. At the same time, they can also increase the strength of concrete, which is why high-grade concrete has strict control over the size of coarse aggregates.

In this process, the fine aggregate after medium crushing is screened out but not into fine crushing. The main reason is that the excessive content of fine aggregate fills the gap between coarse aggregates, reduces the crushing efficiency of fine crushing. At the same time, under the condition of full feeding, it is easy to cause the suffocation of fine crushing equipment and damage the equipment, reduce the service life of fine crushing equipment, and the pre-screening process measures can eliminate this hidden danger.

The third type of process:

The proportion of sand in commercial concrete aggregate is generally about 30%, and the amount of sand is relatively large. Under the current environment of exhaustion of natural sand resources and restriction of mining, machine-made sand has gradually become the trend and mainstream (at present, machine-made sand is mainly used in the construction of large-scale hydropower stations).

At present, machine-made sand mainly adopts vertical impact crusher. Because vertical impact crusher has the function of shaping and crushing, there are relatively many sand-making processes, such as vertical axis autocratic sand without producing coarse aggregates, and some sand-making processes give consideration to shaping coarse aggregates. This process takes into account both sand-making and shaping of 5-10mm aggregates (and all of them). Coarse aggregate is shaping.

The crushed aggregates and fine aggregates enter the screening workshop of the finished product 1, and the crude aggregates of the finished products of 10-20 mm and 20-31.5 mm are screened out. Some of the crude aggregates of the finished products of 10-20 mm and 20-31.5 mm and all the aggregates of 5-10 mm are put into the sand-making adjusting stockpile. After crushing and shaping by vertical shaft impact crusher, it enters the finished product 2 screening workshop for screening. All aggregates larger than 10mm are returned to the sand-making adjusting stockpile to form a closed-circuit cycle, and some more than 5-10mm are returned to the sand-making adjusting stockpile to form a closed-circuit cycle.

In order to adjust the fineness modulus of finished sand (medium sand is usually used to adjust the gradation of sand), some aggregates larger than 3-5 mm after screening are returned to the sand making workshop to form a closed-circuit cycle.

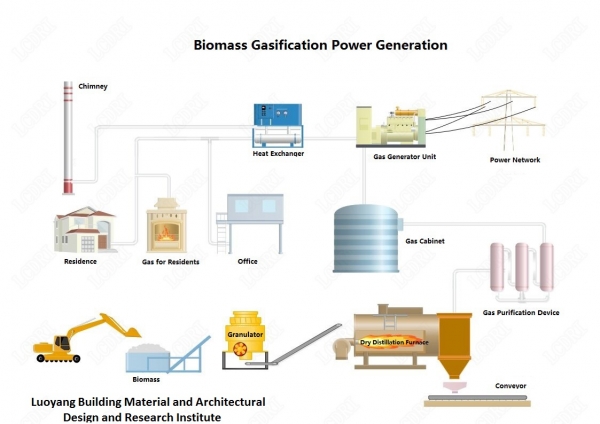

Luoyang Building Material and Architectural Design and Research Institute is a professional building material and building double-A design research institute. It has more than 20 years’ experience in mineral material research. According to the national policy requirements and the customers’ constant pursuit of new technology, it can provide a series of services, such as feasibility study report, design, general package, production improvement and intelligent transformation. Our Institute provides customization according to customers’needs. With the rapid development of gravel aggregate and the expansion of production scale, the design plan and process are based on the product quality, the product plan, equipment and construction site determined according to market conditions, and the environmental sanitation and safe operation are ensured.