Biomass energy is the only renewable energy source that can be stored. It can replace fossil energy to reduce CO2. Therefore, it is a renewable energy with industrialization and large-scale utilization prospects. It is of great significance to the optimization of China’s energy structure. The development of biomass power generation is an important way to build a stable, economic, clean and safe energy supply system and break through the constraints of economic and social development resources and environment.

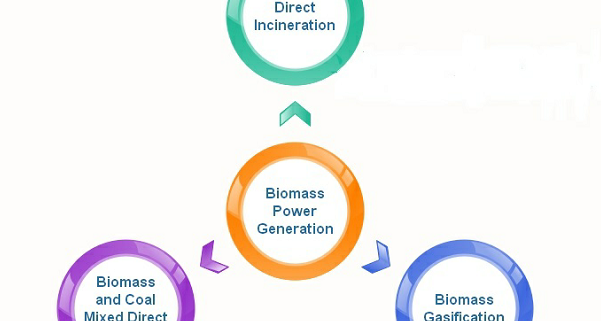

At present, three typical biomass power generation technologies in China are: biomass direct incineration power generation technology, biomass and coal mixed direct combustion power generation technology and biomass gasification power generation technology.

1. Biomass direct incineration power generation technology

Biomass direct incineration power generation is the direct combustion of biomass as a fuel for power generation or cogeneration.

Characteristics of biomass direct incineration power generation technology:

(1) The products of direct incineration of biomass are widely used, and ash can be comprehensively utilized;

(2) Direct biomass incineration can achieve large-scale reduction, harmless and resource utilization of various biomass resources at the fastest speed;

(3) After the direct combustion of biomass, the flue gas needs desulfurization and denitrification, and there is a risk that the atmospheric pollutants such as N0X and SO2 exceed the standard, and there is a risk of dioxin exceeding the standard.

2. Biomass and coal mixed direct combustion technology

Biomass and coal mixed direct combustion is the co-firing of biomass and biomass in pulverized coal furnace. It is a fast and low-cost biomass power generation technology that utilizes active power plants.It is also the cheapest and low-risk technology for generating electricity from renewable sources.

Characteristics of biomass and coal mixed direct combustion power generation:

(1) Pulverized coal combustion has high power generation efficiency, up to more than 35%. Biomass co-firing is the advantage of its high efficiency, which is unmatched by other biomass power generation technologies at this stage;

(2) Biomass burning low sulfur and low nitrogen, can reduce SO2 and N0X emissions from power plants when co-firing with coal powder;

(3) Since the straw-based biomass contains more inorganic substances such as K and Cl, it is easy to cause serious problems such as ash accumulation, slagging, agglomeration and corrosion of the heated surface during the combustion process, which is a serious challenge for biomass direct combustion technology.

3. Biomass gasification power generation technology

Biomass gasification is a technology in which biomass such as straw is heated in anoxic state, and carbon, hydrogen, oxygen and other elements are converted into a combustible gas of carbon monoxide, hydrogen, and methane, and converted into a gaseous fuel. The main combustible components of gasification gas are carbon monoxide, hydrogen, ethylene, methane, etc. It is a clean and clean green energy source.

Characteristics of biomass gasification power generation:

(1) Applicable to carbonization of various biomass raw materials;

(2) The calorific value of the gas is stable, and the generated gas calorific value is 1200-1300kcal/Nm3;

(3) The tar content in the gas is less than 30mg/Nm3, and the tar produced in the furnace passes the catalytic cracking conversion technology, and the tar content in the equipment is greatly reduced;

(4) High power generation efficiency;

(5) The ash after gasification is a good returning potash.

After years of in-depth research, Luoyang Building Material and Architectural Design and Research Institute has made the advantages of self-developed biomass gasification power generation technology more remarkable, and explored a new way for the resource utilization and treatment of agricultural production waste.

Luoyang Building Material and Architectural Design and Research Institute’s biomass gasification power generation technology innovation points:

(1) Modular design, compact structure, easy to install and transport;

(2) Continuous and stable production, which can achieve continuous operation for 300 days;

(3) The equipment adopts the material seal and mechanical seal double seal form, which is safe and reliable;

(4) The system adopts various temperature and pressure sensors and PLC intelligent operating system to realize automatic and efficient control;

(5) Gas washing and dust removal technology, dust removal treatment before hot steam condensation, to meet environmental protection requirements;

(6) The normal production of the system does not require external thermal energy to achieve self-sufficiency in energy;

(7) The normal production of the system can realize the comprehensive utilization of residual energy;

(8) Realize comprehensive energy supply, namely electricity, gas, fertilizer, cold and heat.