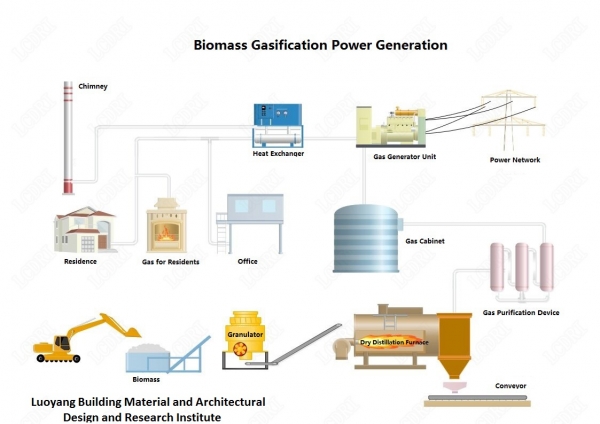

First、Biomass gasification power generation process

Biomass gasification power generation process is divided into biomass pretreatment – biomass anaerobic dry distillation gasification – tail gas treatment and power generation and tail gas waste heat utilization – tailings (carbon) collection and storage.

1. Biomass pretreatment

First, the collected biomass is pulverized, dried and pressed in a dryer to prepare a certain size of particulate matter.;

2. Biomass anaerobic retorting gasification

The particulate biomass is sent to the dry distillation furnace by the conveying device, and the biomass is heated and heated in the dry distillation furnace to decompose the gas, leaving the biomass charcoal (residue).

3. Exhaust gas treatment and utilization of power generation and exhaust gas waste heat

The combustible gas and the water vapor are collected, filtered, and then cooled to separate the water, and the combustible gas is transported into the gas storage tank to be used as a fuel for combustion or for heating in a dry distillation furnace;

High temperature exhaust gas can be used for heating, hot water supply, etc.

4. Tailings (carbon) collection and storage

The lower end of the gas collecting hood adopts a rotary air lock valve body, and the tail slag is transported through the conveyor to the storage tank for packaging.

Second、Main technical features of biomass gasification power generation process

- Continuous and efficient;

- Reliable operation, high gasification efficiency and high gas production quality;

- Gas decoking purification technology;

- Reliable catalysis, condensation and washing technology to remove tar from gas, ensure the cleanliness of gas, and ensure stable operation of power generation system;

- Adopt DCS control system, temperature and pressure data acquisition and transmission to control center to realize one-button operation of control center, manage and control the whole production process;

- Adaptable: It can adapt to different types of branches, leaves, straw and other biomass to generate electricity;

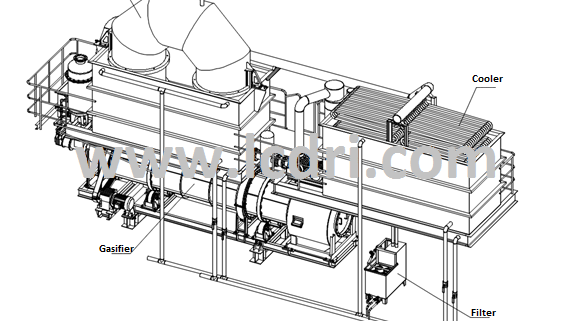

- Modular design for easy transport and installation.

After years of painstaking research, Luoyang Building Material and Architectural Design and Research Institute has independently developed a biomass gasification power generation system that adopts a modular design which is easy to transport and install, compact, safe and reliable, stable in operation, strong in equipment adaptability, and agricultural waste. The resource utilization and processing has contributed tremendous power.