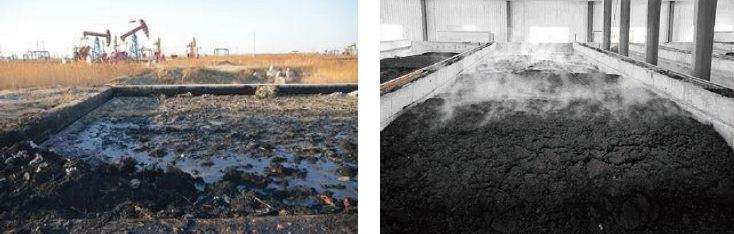

During long-term use of oil tanks, colloids, asphaltenes, high-melting waxes and entrained impurities (such as sand, heavy metal salts, mud, etc.) in crude oil and oil will slowly settle with water. Accumulated in the bottom of the tank to form a thick layer of black gelatinous material called tank bottom sludge. The production and accumulation of oil sludge not only affects the quality of oil, but also affects the use of oil storage equipment. If the oil bottom sludge is not removed in time, it will not only accelerate the corrosion of the tank bottom, but also reduce the service life of the tank, and will have a certain impact on the quality and effective volume of the tank.

Because it contains substances such as phenols and benzenes, the bottom of the tank is odorous and toxic, and the composition is very complicated. Direct discharge is prohibited. The amount is generally as high as 1% to 2% of the tank capacity. Under normal circumstances, the composition of tank bottom sludge is roughly divided into water, emulsified oil or adsorbed oil, solid foreign matter, inorganic salt, etc., generally has high water content, large oil content and contains other harmful substances. The biggest characteristic distinguishing it from other oil sludges is that the hydrocarbon content is extremely high.

The bottom of the oil tank is divided into three layers according to the depth of the mud of different mud ages, namely the initial oil sludge, the upper oil sludge and the bottom oil sludge.

The initial oil sludge is a deposit produced by a new oil reservoir during the settling period and belongs to an unstable silt layer. The layer continues to exchange material with the crude oil layer while new deposits are continuously covering the surface. At the same time, with the change of the operating state of the tank, during the lifting process, most of the paraffin crystals are repeatedly dissolved and recrystallized, and most of them become heavy paraffin with high density, high melting point and coarse granularity. During the constant temperature of the oil tank, heavy paraffin, asphalt micelles, mechanical impurities and water masses in the initial sludge gradually settle to the upper sludge.

The upper layer of oil sludge is the main oil sludge formation layer. Under the repeated influence of the temperature change of the storage tank, the asphalt micelles will continuously gather and fuse into a honeycomb superglue. At the same time, the large amount of liquid hydrocarbons adhering to the outer surface of the micelle, as well as the coarse-grained sediment, water mass, heavy paraffin and mechanical impurities in the gap of the micelle, have been permanently consolidated and become permanent. Oil sludge and layered on top of the oil bottom sludge.

The oil bottom layer of sludge is a stable accumulation layer, which is formed by continuous layering of permanent oil sludge. As the oil storage and time goes by, the mud layer is increasingly solid and thick.

It can be seen that after the initial exchange of materials between the oil sludge layers, most of the micelles slowly descend to the upper layer of oil sludge. Then, the upper layer of the micelles is continuously fused into super micelles, which are then denatured into permanent oil sludge, which is superimposed on the upper part of the oil bottom sludge. As time went by, it continued to reciprocate, eventually forming a large amount of oil tank bottom sludge.