I. Overview of Sandstone Aggregate

Sandstone aggregate is the most basic component of concrete. Usually, 1.3-1.5m_3 loose aggregate is needed for every m_3 concrete. Therefore, for a project with a large amount of concrete, the requirement of sand aggregate is also quite large. The quality of aggregate directly affects the strength of concrete, cement dosage and temperature control requirements, thus affecting the quality and cost of the project. Therefore, in the design and construction of gravel aggregate mines, overall planning should be made, and the components, quality, reserves, physical and mechanical indicators, impurity content, mining, transportation, storage and processing of gravel aggregate should be carefully studied. _

II. Planning of gravel aggregate yard

The planning of gravel aggregate yard is the basis of aggregate production system design. The optimum scheme depends on the distribution and elevation of the material yard, aggregate quality, reserves, natural gradation, mining conditions, processing requirements, the number of discarded materials, transportation mode, transportation distance, production cost and other factors. The planning and optimization of gravel aggregate yard should be carried out through comprehensive technical and economic demonstration. The quality of gravel aggregate is the first prerequisite for material yard selection.

The quality requirements of aggregate include strength, frost resistance, chemical composition, particle shape, gradation and impurity content. The coarse aggregates of cast-in-situ hydraulic concrete are mostly made up of four gradations, namely, 5~20, 20~40, 0~80~120 (or 150) mm. Sand is fine aggregate, which is usually divided into coarse sand and fine sand. Its size gradation is controlled by fineness die. The reasonable value is 2.4~3.2. Increasing aggregate particle size and improving gradation are of positive significance for reducing cement consumption and improving concrete quality, especially for temperature control and crack prevention of mass concrete. However, the natural gradation and design gradation requirements of aggregates are always different, and the reserves of various gradations can not meet the requirements at the same time. This requires more mining or processing to adjust the gradation and its corresponding output. There are three sources of aggregate in construction projects: natural aggregate, artificial aggregate and composite aggregate.

III. Principles of Sandstone Aggregate yard Planning

The following principles should be followed in the planning of sand and gravel yard:

(1) To meet the quality requirements of aggregates for concrete in construction projects, its reserves should satisfy the needs of various design gradations and the necessary affluence;

(2) The selected material yard, especially the main material yard, should be open, elevation appropriate, large reserves, good quality, long mining season, and the main and auxiliary material yard should be able to take into account the requirements of flood and dry seasons for each other;

(3) Choosing a material yard with high recovery rate and close natural gradation to design gradation, and adjusting gradation quantity with artificial aggregate;

(4) There are enough return and stockpiling sites near the stockyard, and less farmland is occupied.

_Choosing a material yard with small preparation workload and simple construction. _

IV. Application of Planning Principles for Sandstone Aggregate Yard

If the above requirements are difficult to meet at the same time, we should meet the main requirements, that is, to meet the quality, quantity and quantity as the basis, to seek a low cost scheme for mining, transportation and processing, and to determine whether to use natural aggregates, artificial aggregates or composite aggregates. If aggregates are combined, the optimum mixing scheme of natural aggregates and artificial aggregates should be determined. Usually for the oversize material in the natural material yard, the shortage gradation is supplemented by processing to form a closed-circuit cycle of the production system, which is a good way to reduce waste and cost. If the natural aggregate scheme is adopted, in order to reduce the discarded materials, the gradation of each material yard should be considered to meet the best combination of the material yard. Obviously, natural material yards with good quality, large quantity and short transportation distance should be preferred. Artificial aggregate is considered only when natural materials are transported too far away and the cost is too high. _

V. Characteristics of Artificial Aggregate

The gradation of artificial aggregate can be easily adjusted to meet the design requirements through mechanical processing. Artificial crushed gravel with rough surface and high cementing strength with cement mortar can improve the tensile strength of concrete and prevent concrete cracking. With the development of large, efficient and durable aggregate processing machinery and the improvement of management level, the cost of artificial aggregate is close to or even lower than that of natural aggregate. Artificial aggregate has many advantages that natural aggregate production does not have, such as adjustable gradation, stable quality, relatively centralized management, less affected by natural factors, which is conducive to balanced production, reduce equipment consumption, reduce stacking site, and the use of effective excavation materials. Therefore, more and more projects using artificial aggregates, such as Yingxiu Bay in Sichuan, Wujiangdu in Guizhou, Dongfeng in Yunnan, Manwan in Yunnan, Dahua in Guangxi, Yantan and other projects using artificial aggregates or mechanical processing aggregates, have achieved obvious technical and economic results in practice.

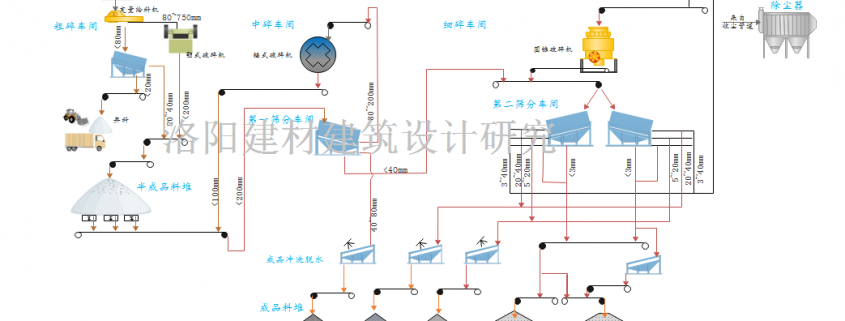

Luoyang Building Material Architectural Design and Research Institute is a professional research institution of building materials and construction grade A. It has more than 20 years’experience in mineral materials research and design and construction of nearly 100 sand and stone aggregate lines. Our institute can provide a complete set of technical services of sand and stone aggregate production line according to customers’ needs: feasibility study report, design, general package, production improvement, intelligent transformation, etc. Providing customers with the latest technology, taking full account of cost savings, investment efficiency, meeting the most stringent environmental requirements, and relieving customers’worries.