Why is the shape of the cooling tower so designed and what are the advantages? This question is actually very easy to confuse people, because various factors are intertwined, in fact, there are several different problems in the middle:

First. The earliest cooling towers had various shapes, such as straight cylinders and octagonal cylinders;

Second. Hyperboloid tower

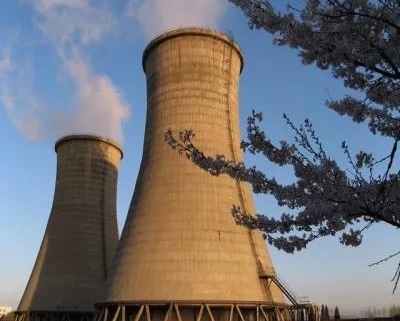

After Iterson first invented the hyperboloid tower in 1915, this configuration quickly became popular in thermal power stations. And with the emergence of large thermal nuclear power plants, there is this kind of natural ventilation hyperboloid cooling tower.

This is a chain of relationships: 1. Increase in installed capacity of power stations — 2. Need to build a larger-scale cooling tower — 3. Cooling capacity is directly affected by area and height, so cooling towers are taller and larger — 4. The tall cylindrical structure is very unstable, and the cost is very high even if it is built-5. It is necessary to use economic means to build a large cooling tower-6. The hyperboloid tower is the most economical;

All thin-shell curved structures have the characteristics of high strength and material saving. There are also cooling towers of other shapes and materials. The exploration of the structure is endless. At present, a typical large cooling tower is about 150m high, and its bottom diameter is about 150m, that is, its bottom can accommodate a football field. However, its thickness is very thin, only 20cm at its thinnest point. If the cooling tower is scaled down to the diameter of the egg shell, it will be thinner than the egg shell, only 1/5 of the thickness of the egg shell.

Third. Why is the hyperboloid structure the most economical?

First of all, according to the structure of the cooling tower, it can be seen that the narrowed design in the middle makes the area of the air inlet larger under the same water spray area, which helps increase the air volume. Therefore this surface should be curved inward.

The reason for the economy of hyperboloids is not because of the most saving of materials, but because of the way it is constructed. Hyperboloids are a kind of ruled curved surfaces that are composed of a straight line through continuous motion, which is its most important geometric property. The straight line rotates around an axis to form a hyperboloid. Therefore, the steel bars do not need to be bent when arranged, that is, they are parallel to the oblique straight line in space. Of course, nowadays, with the increase in size, the construction method of the hyperbolic cooling tower is to cast the concrete in sections.

After years of engineering practice, the mechanical properties and wind-proof performance of this structure have been well tested, and it has become the most common form of cooling tower. Therefore, the use of hyperboloids is also a historical inertia. In fact, in engineering practice, the construction is not completely based on the geometric shape of the curved surface. In actual construction, the curved surface is mostly constructed in sections. Given the radius and thickness of the cylinder wall generatrix, the multi-section flat steel template is used to approximate it. Therefore, strictly speaking, its final shape is different from the hyperbolic busbar. Today’s tower shape is the result of the mutual influence of optimized design, engineering practice and construction habits, and it is different from the geometrical hyperboloid.