Oil Sludge Treatment Rotary Kiln

General Introduction

The oil sludge extraction equipment of LCDRI is mainly used to deal with the oil sludge generated by the accident due to drilling, workover, oil recovery, gathering and storage, etc. during the process of crude oil exploitation. Its function is to separate the waste sludge and extract the refined oil in the sludge, which not only solves the environmental pollution, but also realizes considerable economic value.

CONTACT US

Technical Process

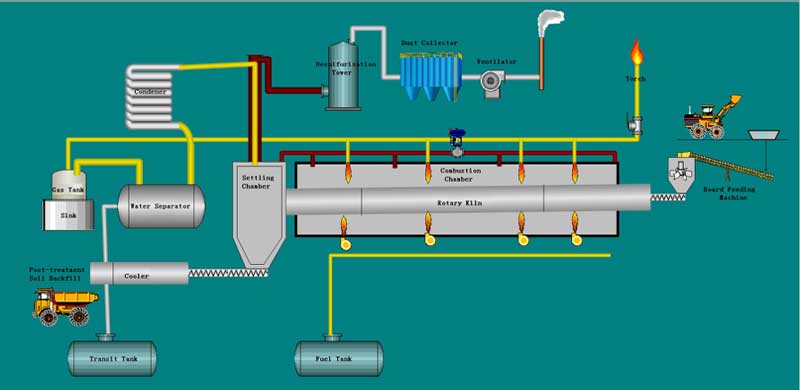

After the mobile sludge treatment device reduces the production of oily sludge, the mud cake is pretreated by sieving, transported by a screw conveyor, and sent to the pyrolysis dry distillation furnace for evaporation separation from the feed hopper. The pyrolysis dry distillation furnace is a The rotary rotary kiln has a hot air passage outside, and the high temperature hot air in the passage provides heat for the sludge to evaporate. The hot air passage is connected to the burner, and the burner is burned inside the combustion chamber. The oily sludge is moved from one end to the other under the action of continuously turning in the dry distillation furnace to complete the heating process. During the heating process, the volatile organic matter in the material is volatilized by heat to form an oil and gas mixture, which is discharged into the condensation chamber from the tail portion of the dry distillation furnace, and the solid dry residue material that has reached the standard after evaporation is discharged from the lower end of the tailing of the dry distillation furnace.

The oil and gas condensation recovery unit is mainly carried out in the spray tower. In the spray tower, the oil and gas mixture is in direct contact with the sprayed low-temperature condensate, and the majority of the oil and gas is condensed. The formed oil-water mixture is discharged into the subsequent oil-water separation unit, and a small amount of non-condensable gas is sprayed into the burner as a combustion-supporting gas by the spray washing gas to reduce the amount of natural gas, thereby reducing part of the running cost. In the oil-water separation unit, the oil is dewatered by the first grade sloping plate, the second-stage condensate filter is degreased, and the oil is floated and degreased. The oil content in the water drops below 10 ppm. After the deoiled water is cooled by the air cooler, it is circulated into the spray tower for spraying, and the light oil separated from the unit is stored in a recovery tank. A small amount of water is generated during the oil-water separation process, and is used as humidifying water after microfiltration according to requirements, and is used for humidifying and cooling the solid discharge or discharging the heavy metal to be harmlessly treated, and the whole process has no external sewage.

Oil Sludge Rotary Kilns Technological Advantages

- Armored modular design for quick installation and transportation.

- A wide range of applications: suitable for processing a variety of oily waste, tank bottom sludge, oil sludge sludge oil sands, oil-based cuttings and so on. It can also be used for soil remediation, organochlorine pesticides, polychlorinated biphenyls, furans, pharmaceutical and chemical solid waste treatment. It can also be applied to the disposal of waste tires, waste plastics, and waste paints.

- The thermal desorption system can be continuously and uninterrupted, the processing capacity can reach 3 to 15 tons per hour. The treated solid oil content can be less than 0.3%, meeting the most stringent environmental requirements in China.

- Self-cleaning screw pusher design, can meet the continuous processing of high viscosity materials, reducing cleaning and maintenance time.

- The system uses a variety of sensors, PLC intelligent operating system to achieve fully automatic and efficient control.

- Advanced gas dust removal technology, dust removal treatment before hot steam condensation, effectively reducing the solid content of the condensate, thereby reducing the processing cost.

- Comprehensive utilization of tailings to achieve value enhancement.

- The equipment is operated under negative pressure and is safe and reliable.

- The recycled water is reused, the sales of the recovered oil is appreciated, and the emitted gas is environmentally friendly, and there is no waste discharge. The entire pyrolysis system achieves zero emissions.

Specifications

|

S.N. |

Name |

Specification |

Heating Method |

Heating Temperature(℃) |

Production Methods |

Processing Capacity(t/h) |

|

1 |

Pyrolysis Rotary Kiln |

LY05_01 |

Indirect Heating |

420~500 |

Intermittent |

3.5~5 |

|

2 |

Oil Sludge Rotary Kiln |

LY08~02 |

Indirect direct heating |

400~550 |

Continuous |

3~15 |