Sludge rotary kiln

Product Name

Sludge Treatment Rotary Kiln Incinerator

Sludge treatment rotary kiln incinerator introduction

The heating source of the sludge treatment rotary kiln incinerator is at the head of the incinerator tube, and a large amount of hot air is generated by combustion to heat the sludge in the furnace, so that the material in the incinerator tube reaches the required gasification temperature; the equipment is mainly applied to the high temperature. Gasification, heating the sludge, the maximum working temperature of the incinerator can reach 700 °C; direct heating by material circulation. The rotary kiln incienerator has a solid structure, stable operation, and complete decomposition and gasification of organic matter.

CONTACT US

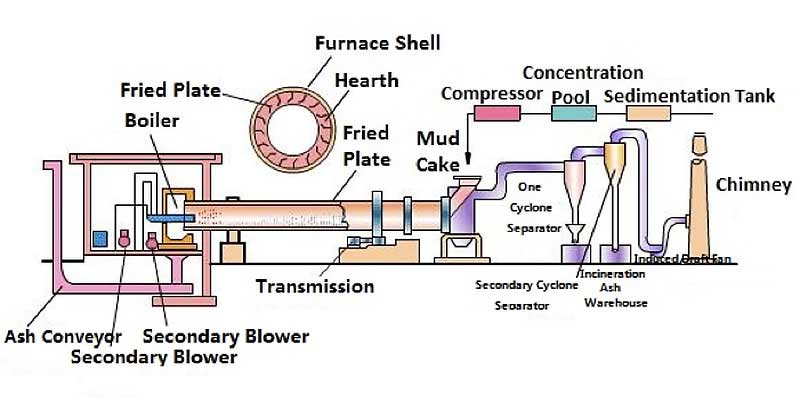

Sludge rotary kiln structural principle

The incinerator head part: the incinerator head is the discharge part of the rotary kiln incinerator, the diameter is larger than the diameter of the rotary kiln incinerator, and the seal is realized by the stainless steel fish scales and the incinerator body. The main components are the inspection port, the coal injection burner, the trolley, and the observation hole.

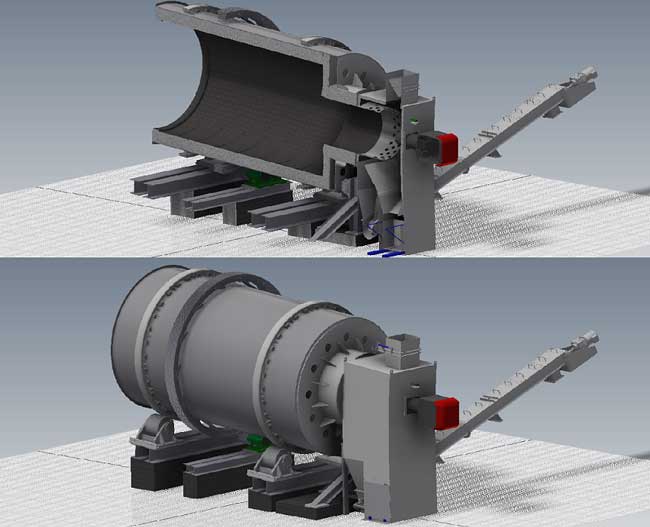

The incinerator body part: it is the main body of the rotary kiln incinerator, usually 30~150 meters long, cylindrical, with 3~5 load-bearing roller rings in the middle. The cylinder is processed into a plurality of sections at the factory and connected to the destination after transportation. The roller ring is partially cast, and the incinerator body of the roller ring is slightly thicker than other parts of the kiln plate. In order to ensure that the steel in the normal operation of the rotary kiln incinerator is affected by heat, the inner surface of the rotary kiln incinerator is usually lined with refractory materials of different thickness.

Supporting tug: It is the part that lifts the incinerator and rotates. Usually a set of rollers consisting of two rollers and two retaining wheels.

The incinerator tail part is an end cover that seals and feeds at the feed end of the rotary kiln incinerator.

SLUdge Carbonization Rotary Kiln Incinerator Technical Advantages

- Dry distillation treatment of sludge, strong adaptability to sludge water, water content ≤ 80% can be treated;

- The pyrolysis temperature is above 600 °C, and the pathogenic microorganisms and parasites in the sludge are completely killed;

- The system equipment is simple to operate, easy to maintain, able to maintain continuous and stable operation throughout the year;

- The product is bio-organic carbon, which has wide application and good economic value;

- Adopt automatic control and real-time monitoring, convenient control and stable parameters;

Sludge Carbonization Rotary Kiln Incinerator Technical Characteristics

- Dry distillation is carried out under sealed, oxygen-free, non-combustion and high temperature conditions, avoiding the production of dioxins, nitrogen oxides and so on.

- The mixture gas (steam and non-condensable combustible gas) produced in the process of sludge retorting is purified and separated, and the combustible components such as methane and ethane are used as the fuel of the retorting sludge unit.

- Clean gas fuels such as gas are used in the treatment of sludge by dry distillation, and the tail gas produced by the fuel after combustion in the combustion chamber reaches the national standard.

- Sludge is directly transported to the retort unit for treatment, which avoids bacterial fermentation, odor and air pollution.

- The water vapor produced in the process of sludge treatment by dry distillation is condensed, recovered and purified to become condensate, and the condensate is recycled and discharged as cooling water.

- The sludge treatment unit of dry distillation is equipped with dust removal equipment. In the process of dry distillation, biochar dust can be prevented from polluting the environment and protecting the working environment and health of the operators.

Specifications

|

Spec (m) |

φ2.8/2.5×44 |

φ3.2×52 |

φ3×48 |

φ3.2×50 |

φ3.2×50 |

φ3.3×50 |

φ3.5×54 |

||

|

Production Capacity (t/d) |

300 |

600 |

700 |

1000 |

1200 |

1200 |

1500~1800 |

||

|

Kiln Slope (%) |

3.5 |

3.5 |

3.5 |

3.5 |

4 |

4 |

4 |

||

|

Number of Supports (pc) |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

||

|

Wheel Form |

Machinery |

Mechanical or Hydraulic |

Mechanical or Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

Hydraulic |

||

|

Kiln Speed |

Main Drive (Rev/Min) |

0.445-2.22 |

0.676-3.38 |

0.676-3.38 |

0.36-3.57 |

0.4-4.07 |

0.36-3.57 |

0.39-3.9 |

|

|

Auxiliary Drive(Rev/h) |

4.75 |

9.36 |

9.36 |

6.5 |

6.5 |

5.61 |

7.66 |

||

|

Main Drive |

Electric Motor |

Model |

ZSN4-225-21 |

Z2-101 |

ZSN4-280-091B |

ZSN4-280-091B |

ZSN4-280-091B |

ZSN4-280-11B |

ZSN4-315-092 |

|

Rated Power(KW) |

55 |

100 |

160 |

160 |

160 |

190 |

220 |

||

|

Speed Range(Rev/Min) |

~1500 |

~1500 |

~1500 |

~1500 |

~1500 |

~1500 |

~1000 |

||

|

Rated Voltage(V) |

440 |

440 |

440 |

440 |

440 |

440 |

440 |

||

|

Reducer |

Model |

ZS145-1-I |

ZS145-1-I |

ZS145-1-I |

ZSY450-40-V |

ZSY450-40-V |

ZSY450-40-V |

NZS995-28VIBL |

|

|

Total Speed Ratio |

49.63 |

49.63 |

40 |

40 |

40 |

40 |

28 |

||

|

Speed Measuring Generator |

Rated Power (K) |

22 |

22 |

22 |

22 |

22 |

22 |

22 |

|

|

Speed Range(Rev/Min) |

0~2000 |

0~2000 |

0~2000 |

0~2000 |

0~2000 |

0~2000 |

0~2000 |

||

|

Max. Voltage (V) |

110 |

110 |

110 |

110 |

110 |

110 |

110 |

||

|

Auxiliary Drive |

Electric Motor |

Model |

Y122M-4 |

Y160M-6 |

Y160M-4B |

Y160M-4B |

Y160M-4B |

Y160M-4B |

Y200L1-6 |

|

Rated Power(KW) |

4 |

7.5 |

15 |

11 |

11 |

15 |

18.5 |

||

|

Speed Range(rev/min) |

1440 |

970 |

1460 |

1460 |

1460 |

1460 |

970 |

||

|

Rated Voltage(V) |

380 |

380 |

380 |

380 |

380 |

380 |

380 |